DP Project

DP Project s.r.l. develops and manufactures projects and products in thermoplastic material.

Mission and vision

Being an international reference point for the real development of ideas in the field of thermoplastic injection molding, guaranteeing the highest quality technological solutions for the customer. Fully satisfying the needs of all the stakeholders, proactively creating and maintaining long-term relationships.

Providing accurate answers in every moment of the productive process, with availability and flexibility towards the needs and the desires of our customers. Investing in the research in the field of thermoplastic material.

Company

Values

COMPLETE AND INTEGRATED SERVICE

DP Project provides: analysis of the customer’s request; design of the product according to the customer’s specific requirements; engineering, prototyping and construction of pilot molds; realization of the final plastic product; after-sale support.

QUALITY AND FLEXIBILITY

DP Project is the solution for those looking for a partner that can provide both high-quality products and a fast, effective and flexible service. Our solutions are custom-tailored for each individual order.

PASSION AND COLLABORATION

DP Project‘s staff is passionate and motivated, and the customer is the focus of all of their activities. DP Project engages its customers in a collaborative relationship based on co-operation and trust, in order to reach together the established goals.

INNOVATION AND EXPERIENCE

DP Project uses advanced technologies to manage the entire supply chain: it is a process of constant innovation, research and improvement based on a specialized know-how gained in over sixty years of experience passed down from generation to generation.

Services

Planning

Planning

From the customer's idea, we develop a personalized proposal to meet their needs.

Engineering

Engineering

From the customer's idea, we develop a personalized proposal to meet their needs.

Prototyping

Prototyping

We create 3D molds to test the project; we realize prototype molds for pre-production plastic samples. We also work together with a technical office for the structural test of the product.

Construction

Construction

With CAD-CAM systems, we use the engineerized 3D file to realize molds for thermoplastic injection.

Production

Production

We mold using 50-600 tons machines and the best commercially available polymers and we pre-assemble the semi-finished products.

After-sale care

After-sale care

We provide assistance for any after-sale needs, with particular attention to the specific request of every single customer.

A project with DP Project

Products

Factory sound

MoldsR&D

R&DFast Prototyping

R&DDesign

R&DMold in process

MoldsMold in process

MoldsMold in process

MoldsMold in process

MoldsMold in process

MoldsMold in process

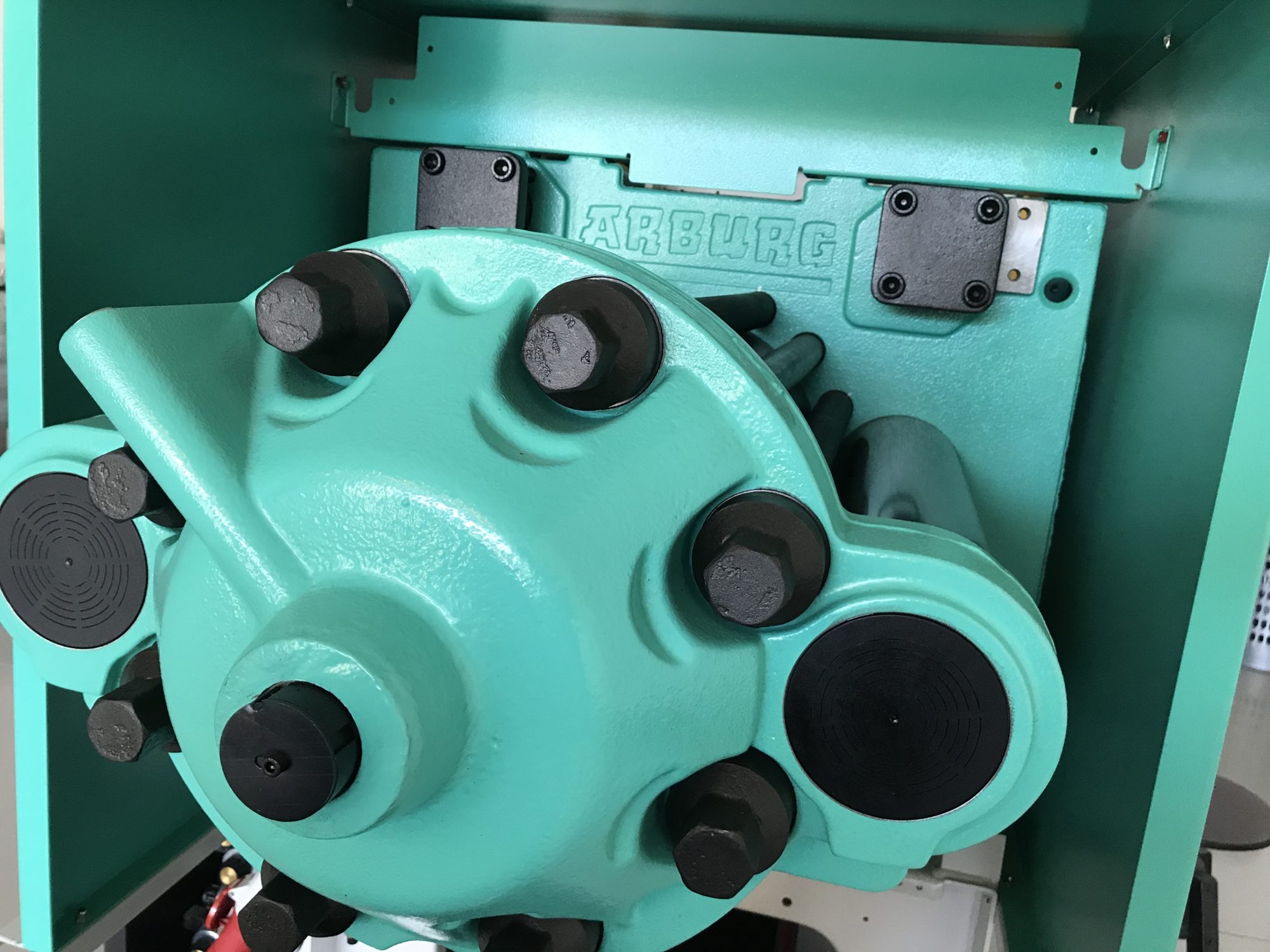

MoldsPress Equipment

MoldsMolds

MoldsMold in process

MoldsMolds

MoldsAir Pistol

R&DWall display board

ProductsPressure pump

ProductsPorsche Cayenne 2015

ProductsAlfa Giulia 2014

ProductsVolvo 2013

ProductsGuide light kit – BMW 7 SERIES

ProductsSuction nozzle

ProductsCold room hooking system

ProductsGear wheel

ProductsRear light bulkhead Alfa Giulia

ProductsCable tie

ProductsElectrical connector

ProductsPiezoelectric cover

ProductsSpool for electromagnetic brake

ProductsDisplay and PCB seat

ProductsPotentiometer for aerial platforms

ProductsBoiler filter component

ProductsKitchen space organizer

ProductsVaporizer

ProductsDispenser

ProductsR&D

R&D

Certification

Location

Contacts

Address

Via della Cooperazione, 27 – 38123 Mattarello (TN) – Italy

Monday – Friday 8:30 – 18:00

Phone

+39 0461 1920662

Fax

+39 0461 1739455